Khoom nta

1 、 Kev tiv thaiv ib puag ncig siab

Kev xaiv etching tuaj yeem ua tiav yam tsis tas siv cov khoom siv cawv xws li IPA.

2 、 Cov nqi tsim khoom tsawg

Cov nyiaj ntxiv yog tsawg, lub sijhawm texturing tsuas yog siv sijhawm 6 mus rau 8 feeb, thiab tus nqi qis dua li IPA texturing txheej txheem.

3 、 Kev txhim kho kev ua tau zoo heev

Piv nrog rau cov txheej txheem IPA texturing, kev ntxhib los mos uniformity thiab kev xav tau zoo dua.

4 、 Tsis muaj txheej txheem polishing pib

Tus nqi txo qis heev, thiab cov additive nws tus kheej yog ntau tus phooj ywg environmentally.

Technical Parameters

| Cov khoom xyaw | Cov ntsiab lus | CAS Nr. | EC No. |

| Dej ntshiab | 95-97% | 7732-18-5 ib | 231-791-2 : kuv |

| Sodium lactate | 2-2.5% yog ' | 532-32-1 : kuv | 220-772-0 ib |

| Sodium epoxysuccinate hmoov | 1-1.5% | 51274-37-4 | / |

| Surfactant | 0.01-0.05% | / | / |

| Preservative acid | 0.1% -0.2% | 137-40-6 : kuv | 205-290-4 ib |

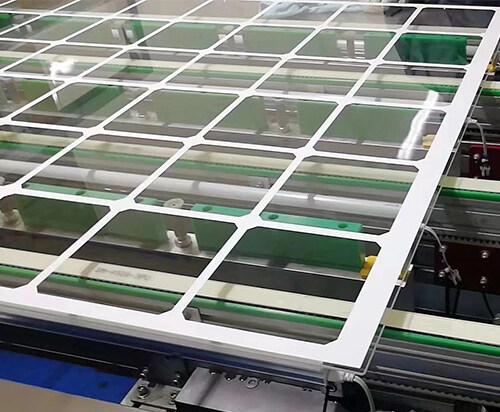

Daim ntawv thov Range

Cov khoom no feem ntau haum rau Perc, Topcon thiab HJT cov txheej txheem roj teeb

Haum rau ib qho crystals ntawm 210, 186, 166, thiab 158 specifications

Lub cev nta

| Tsis muaj. | Yam khoom | Main parameters thiab project indicators |

| 1 | Xim, puab | Tsaus xim av kua |

| 2 | Tus nqi PH | 13-14 |

| 3 | ceev | 1.1-1.9g / ml |

| 4 | Cia tej yam kev mob | Khaws ntawm chav tsev kub kom deb ntawm lub teeb |

Cov lus qhia

1, Ntxiv qhov tsim nyog ntawm alkali (1.5 - 2.5% raws li qhov ntim piv ntawm KOH (48%)) rau hauv lub tank.

2, Ntxiv qhov tsim nyog ntawm cov khoom no (0.5 - 0.8% los ntawm ntim) rau hauv lub tank.

3 、 Ua kom sov lub tank ua kua rau 80 ℃ + 4.

4, Muab cov silicon wafer rau hauv lub tank texturing, thiab lub sij hawm tshuaj tiv thaiv yog 400s-500s.

5, Pom zoo poob phaus rau ib zaj duab xis: 0.45 + - 0.06 g (210 zaj duab xis qhov chaw, lwm qhov chaw ua yeeb yaj kiab tau hloov pauv hauv qhov sib npaug).

Siv Case

Noj Jiejia Veichuang trough-type texturing khoom ua piv txwv, cov txheej txheem tsis yog thawj polishing yog siv.

| Txheej txheem tank | Dej ntshiab | Alkali (45% KOH) | Ntxiv (JUNHE®2550) | Sijhawm | Kub | Poob poob | |

| Texturing | Ua ntej ua kua | 4 37,5l | 6 L | 2.5 l ua | 420s ob | 82 ℃ | 0.47 ± 0.03g |

| Ua kua infusion | 9L | 500 ML | 180 ML |

Cov kev ceev faj

1 、 Cov khoom ntxiv yuav tsum tau khaws cia nruj me ntsis ntawm lub teeb.

2, Thaum cov kab ntau lawm tsis tsim, cov kua dej yuav tsum tau ntxiv thiab ntws tawm txhua 30 feeb.Yog tias tsis muaj ntau tshaj 2 teev, nws raug nquahu kom ntws thiab rov ua cov kua dej.

3 、 Cov kab tshiab debugging yuav tsum muaj cov txheej txheem sib txuam raws li txhua tus txheej txheem ntawm cov kab ntau lawm kom ua tau zoo tshaj plaws.Cov txheej txheem pom zoo tuaj yeem raug xa mus rau kev debugging.